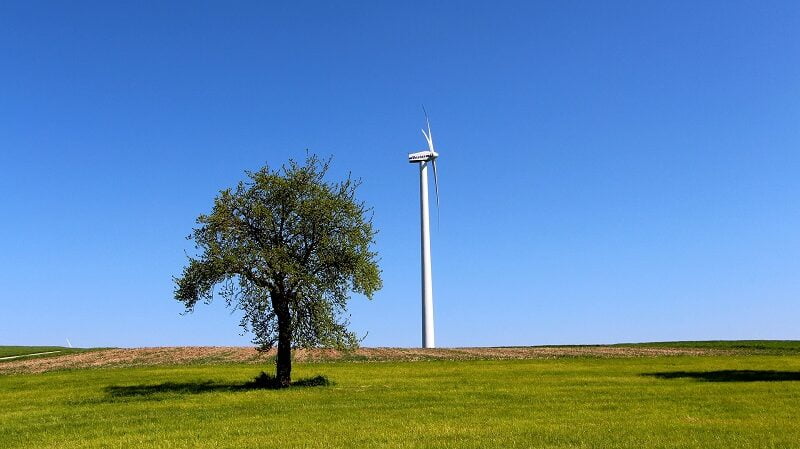

Researchers from Michigan want to develop a wind turbine that will one day be processed into gummy bears after its operating time. Other products are also conceivable.

In the coming years, the expansion of renewable energies will become increasingly important. The Ukraine war in particular shows how dependent we are on fossil fuels. A circumstance that politicians want to change soon.

But in addition to their many advantages, solar and wind power plants also have a decisive disadvantage: What to do when the solar cells or rotor blades have had their day? Researchers around the world have been dealing with this problem for several years.

Only recently, the Siemens Gamesa group presented recyclable rotor blades, a concept that could set a precedent in the coming decades. Another new approach now comes from Michigan State University. The turbines of wind turbines should be given a second life in many products after their service life.

New wind turbine rotor blades open up huge potential

In theory, many companies could use previously available wind turbines as building materials after they have been used. In practice, however, the huge constructs usually end up in landfills. In addition to the raw materials that can no longer be used, this is also a problem due to the space requirement.

However, a newly developed resin made from glass fibers and polymers could soon change that. Rotor blades based on this solution could be mixed with minerals after use. As a result, products such as toys or other plastic products are created. Other possible uses are plastic discs or even gummy bears.

Everyday tests should show the stability of the new rotor blades

Gummy bear? Yes, you read that right. During further processing, potassium lactate is produced, a raw material that can be used for gummy bears. So maybe one day we’ll eat a pinwheel. Due to its diversity, the process opens up almost infinite potential.

In the next step, the researchers want to produce the first rotor blades and test them in everyday use. Because it is not yet entirely clear how the material will fare in snow, rain and wind. If the rotor blade withstands the conditions, the process can be scaled up to industrial level within a short period of time.

Also interesting:

Source: https://www.basicthinking.de/blog/2022/08/29/windrad-gummibaerchen/