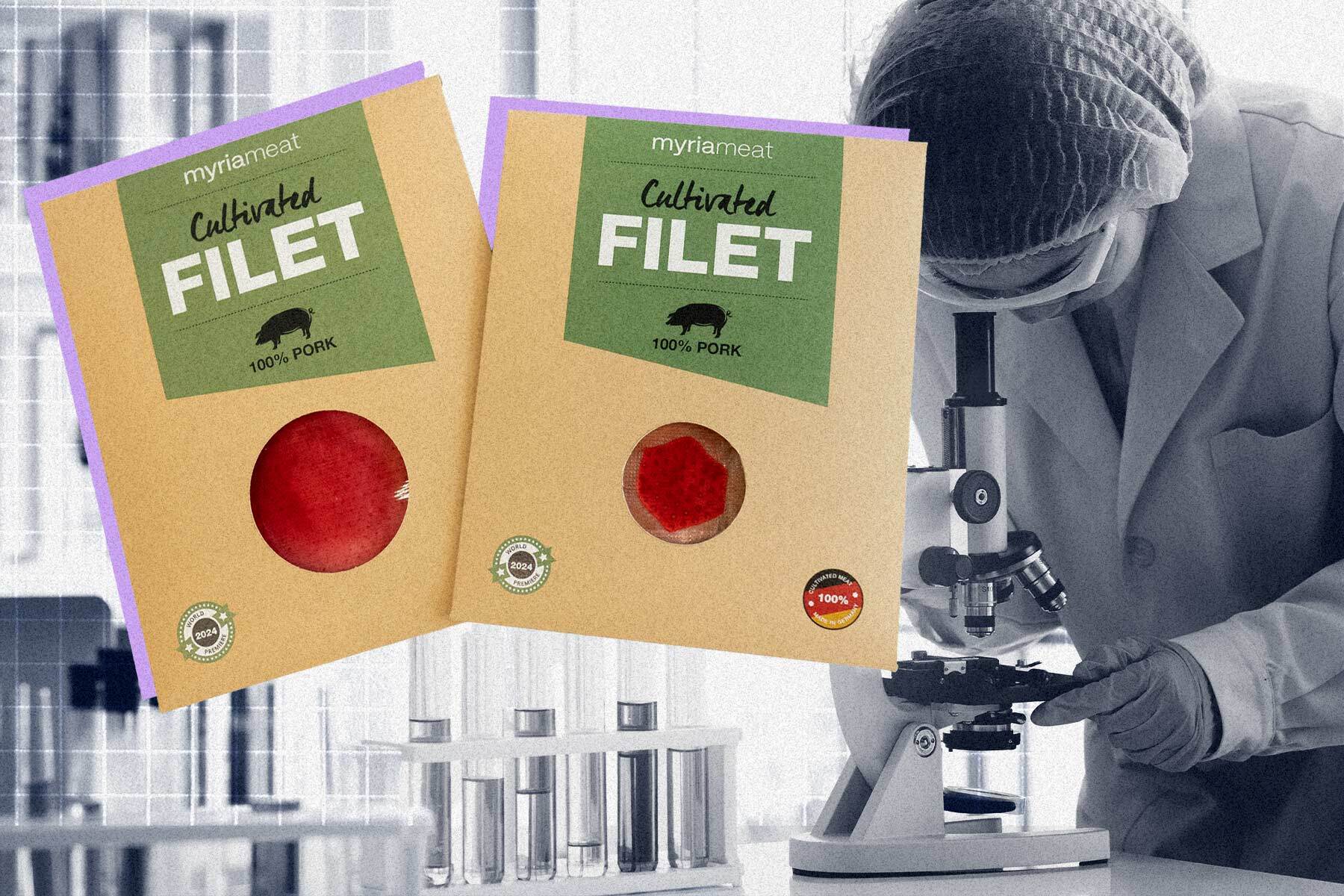

Meat factory of the future – made in Germany. That is the goal of Myria Meat. The startup produces real pork from animal stem cells.

“We make meat without animals,” explains Myria Meat CEO Florian Hüttner. More precisely: his startup produces pork without pigs having to die. What he does is called cultivated meat. It is identical to the meat that people eat today. However, it is grown directly from animal cells.

The startup, founded in 2022, has developed a technology that can be used to grow stem cells taken from animals in bioreactors and thus produce real meat. One stem cell from a pig is enough to produce an infinite amount of pork. “The cells divide permanently, without genetic changes,” explains Hüttner. All you need for this is “a few milligrams of tissue.” You can imagine it as if a dermatologist removed a mole, explains Hüttner. The cells from animals that have already been slaughtered can also be used, or they can be obtained by taking blood. But Myria Meat has opted for stem cells from a country pig that “grew up normally.” All of this sounds promising, but how exactly does it work?

First the research, then the idea

In contrast to other companies that already had the idea of producing “meat without animals,” Myria Meat was founded on the basis of basic research. That means, first the research, then the idea. The startup's beginnings go back to research results from the University of Göttingen. Professor Dr. Wolfram Zimmermann, co-founder of Myria Meat, heads the Institute of Pharmacology at the University Hospital of Göttingen. He and his team developed heart muscle cells for humans that are used in human medicine. Hüttner and Zimmermann then came up with the idea of transferring this technology to animals in order to produce cultured meat.

Read also

The starting material for production is so-called pluripotent animal stem cells. These are cells from which any organ or tissue can develop. These cells are multiplied in a bioreactor, grow and divide. “In the reactor, we make small cell aggregates that contain not only muscle cells, but also connective tissue cells and fat cells,” explains Hüttner. Meat-like products can already be made from the resulting mass. For example, by adding plant proteins. This is then called “hybrid cultivated meat products.” But Myria Meat does not do that. “That's where the magic begins for us,” says Hüttner.

Finished meat in six weeks

Instead of removing the mass, the company lets the cells continue to grow. “Other companies have dead cells and we have living, real cells that move and contract,” he explains. Just like animals, the cells also need to be fed. That's why Myria Meat adds effervescent tablets containing proteins, amino acids and salts to the cells in the reactor. The effervescent tablets dissolve and the cells then float in the liquid. Through further growth in the bioreactor, Myria Meat develops muscle tissue from the animal that can be trained. And from this, meat can be produced. Because meat is muscle.

Read also

The company is currently concentrating on producing pork, which is the easiest. But the process is identical for every animal species, you just have to work with different cells. At the same time, Myria Meat is also working on beef, lamb and deer. “We are initially concentrating on the large animal species that have the greatest impact on the environment,” says Hüttner. Cows are considered the biggest climate sinners in the animal kingdom. The production of cultivated meat should save 80 to 90 percent of the footprint of conventional meat production from animals, says Hüttner. This includes water, CO2 and agricultural land and the associated deforestation.

The process to produce the finished meat takes six weeks. “A cow needs two years, a pig eight months, and for us it takes six weeks,” says Hüttner. By this he means the time until the animals are slaughtered.

“We are pro-farmers”

The company is currently still in the laboratory phase. But the first prototype already exists. “Within a year, we transferred the process from humans to animals and proved that our process can produce real animal muscle,” says Hüttner. A factory of its own with bioreactors may come next year. But for that, Myria Meat needs a large round of financing. “For scaling and for approval,” explains the CEO. Approval in Germany is a “not insignificant” process. But his team has an advantage because the process has already been tested and approved in the medical field. The first larger fillet is to be produced this year.

Myria Meat does not see itself as competition to manufacturers of meat substitutes such as Beyond Meat or Planted. “These are alternative protein manufacturers who do not have the motivation to produce meat. That is not what we do. We make meat. That is a huge difference,” says Hüttner. They do not want to replace traditional farmers either. “We do not want to displace anyone. We are pro-farmers,” he continues. After all, agriculture is also a cultural asset. The company wants to create a counterweight to factory farming. Because when it comes to meat consumption, “humanity has taken a wrong turn somewhere, and that is where we are starting,” says Hüttner. “We want to encourage conscious meat consumption.” Myria Meat has received positive feedback from vegetarians. According to Hüttner, they would “then eat meat again”. Myria Meat does not know whether the cultivated pork would also be accepted by vegans. “That would be interesting to hear,” says Hüttner.

Read also

Meat factory of the future

The Myria Meat team is led by Hüttner, Gunther Zimmermann (Co-CEO) and Timm Eiffler (CMO). In addition to the management, the team mainly consists of scientists, the laboratory team. In contrast to other suppliers of cultured meat, Myria Meat has a head start thanks to decades of research. Even multimillion-dollar VC financing rounds cannot compensate for this head start, says Hüttner. Myria Meat does not need to expand its team much, because the process is already there. The goal is to build a “meat factory of the future”. “Ideally made in Germany,” adds Hüttner.

This article first appeared in May 2024.

Source: https://www.businessinsider.de/gruenderszene/business/cultivated-meat-wie-dieses-startup-vom-menschlichen-herzmuskel-zum-schweinefilet-kam-08/